The waste-reduction legislation just passed in Ontario will please consumers, who will no longer have to pay so-called eco fees when they buy a new television, fees that can add up to $39.50 to the cost of the item. The law will also place more responsibility on producers to design products and packaging for reuse and recovery. Glenn Murray, the Minister of the Environment and Climate Change, said manufacturers will have to cover the cost of recycling, a responsibility that will incentivize them to design products with end-of-life costs in mind. The province’s goal in passing the new law is to take Ontario closer to achieving a “circular economy.”

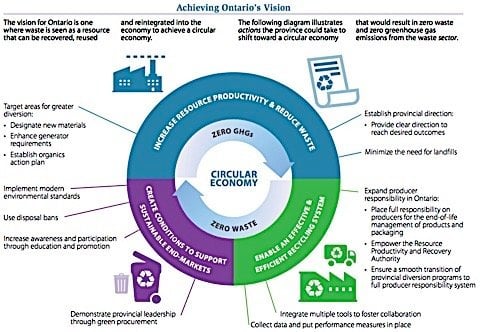

By definition, a circular economy is one in which there is zero waste, zero greenhouse gas emissions from the waste sector, and where all resources, organic and non-organic, are used and reused for the benefit of the economy. As of today, the province is far from that goal. According to its own numbers, greenhouse gas emissions from waste actually rose by 25 per cent between 1990 and 2012, and the amount of waste sent to landfills has increased. The government says that $1 billion worth of recoverable materials are simply thrown away each year.

The overall diversion rate in the province—the total amount of organic and non-organic waste handled by the various recycling programs in place throughout the province—has stalled at just 25 per cent. Ontario will run out of landfill space within two decades at current rates of disposal.

Showing that better results can indeed be had is Sweden, a country that has reportedly achieved a 99 per cent diversion rate. So successful has Sweden been in its waste management that it now has to import trash from other countries to fuel its waste-to-energy plants, which provide a large proportion of its energy needs. Half of Sweden’s own trash is converted to energy as well. Garbage is now said to be regarded as a valuable commodity in Sweden.

This makes sense if one considers that three tons of waste contain as much energy as one ton of fuel oil. It means that the millions of tons of waste in landfills in Ontario and elsewhere are a potentially valuable resource literally going to waste. By the government’s reckoning, every 1,000 tons of waste diverted from landfill generates seven full-time jobs, $360,000 in wages and $711,000 in GDP.

While Sweden has been making producers pay all costs related to recycling their products for several years now, Ontario’s producers are required to finance diversion programs by paying industry funding organizations (IFOs). These include the Ontario Tire Stewardship and the Ontario Electronics Stewardship. They were set up under the 2002 Waste Diversion Act and will “eventually” be eliminated under the new law.

The government says that those IFO programs cover only 15 per cent of the total waste stream, and they disincentivize producers to improve their products’ design and reusability. What’s more, the burden for waste disposal, which reached $2.9 billion in Canada in 2010, has been largely borne by taxpayers. But “empowering” producers with full responsibility will give them a tool for fulfilling their responsibility cost effectively. That responsibility includes how the product is designed, used, reused, and “reintegrated” into the economy at its end of life.

The success of the plan will depend on three critical objectives being met: resource productivity must be increased in order to reduce waste; an efficient and effective recycling system must be put in place; and there must be a market for recovered materials.

To make recycling economically viable, the government will need to emphasize the development of markets for recovered materials. This requires coordinated actions using multiple tools to capitalize on the economic opportunities associated with collection, transportation, processing and re-integration of resources into Ontario’s economy.

On that last objective, market viability, some materials are clearly more valuable than others. Copper, for example, has such a high recycling value that premium grade scrap retains at least 95 per cent of the value of the primary metal from newly minted ore. Almost 40 per cent of world demand for copper is met with recycled material, the government says. Recycled copper is used in the same applications as primary copper: electrical wiring and circuitry, piping, roofing and insulation and household items like cookware.

To make the recycling of other materials viable economically, it must be more profitable than just sending them to landfill. The government says it will work to develop markets for recovered materials.

Under the new Ontario law, consumers will very likely see a lot more in the way of public awareness campaigns in coming months, with greater emphasis on organics recycling, for one thing, particularly in high-rise condos and rental apartments. There may also be more disposal bans coming, making it illegal to throw away certain waste substances. Some jurisdictions have banned food waste, for example. The value of wasted food is estimated at $31 billion in Canada each year. Up to 40 per cent of all the food produced and sold in Canada is wasted. Such bans cannot be implemented, the government concedes, without providing people an alternative.

For industry, the government intends to designate certain new materials under the producer responsibility regime, including printed paper, products and packaging, and construction and demolition waste. Fluorescent bulbs and tubes, household electronics appliances, carpets, mattresses and batteries are some of the products that could be included in the producer responsibility plan.