GE said in a statement today that the Federated Co-Operatives Limited refinery complex in Regina is installing GE wastewater treatment technology that will enable it to clean 100 per cent of its wastewater on site. The Regina facility will be the only refinery in North America with the capacity to recycle all of its wastewater for steam production. Steam is used for heating, hydrogen production and to power equipment for cooling towers.

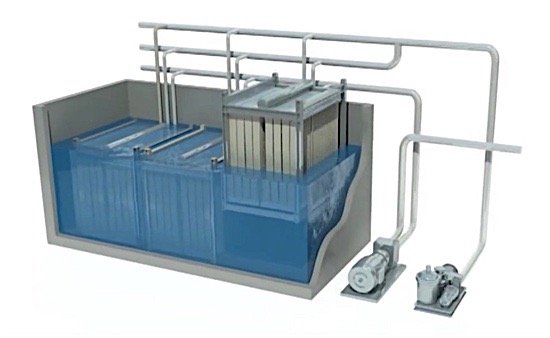

At present, the refinery, which has a capacity of 130,000 barrels per day, uses a blend of well water and city water. Faced with restricted use of city water, the refinery had to find a new source of water. GE offered a solution that combines its ZeeWeed membrane bioreactor (MBR) technology and a high-efficiency reverse osmosis (HERO) system to recycle and reuse up to 2 million gallons of wastewater a day. According to GE, once the system is running, the refinery will reduce its use of freshwater by 28 per cent. It will also “significantly decrease” volatile organic compounds emissions from its wastewater ponds and reduce “nuisance” odours.

The amount of water used in refining is staggering. It takes on average 2.5 gallons of water for every gallon of crude oil processed. The cost of water-related expenditures in a large refinery can be more than $100,000 per day.

Water is a precious resource and our wastewater improvement project allows us to be efficient and sustainable by recovering every drop of water. With GE’s technology, the Co-op Refinery Complex will clean and recycle all of its wastewater in a socially responsible and environmentally sound way to conserve water for Regina and the entire province of Saskatchewan.

Wastewater streams are used in several different stages of refining, from washing the crude to remove salts and “sour” water before processing begins, to cleaning sediments and chemical buildups from the bottoms of tanks and boilers. There may also be runoff water to contend with, from storm events, as well as ballast water from tankers.

The wastewater from refineries typically contains high levels of pollutants, including sulfur, nitrogen, dioxin, PCBs, and metals, which can include mercury, chromium and antimony. The Regina refinery, which has reportedly spent $200 million on its wastewater improvement plan, is currently concentrating on removing volatile organic compounds from the water destined for holding ponds. Removing brine and salts so that water can be reused is the next step. When the GE system is fully operational, expected to be this fall, the refinery will be able to recover “every drop” of water used.

GE’s ZeeWeed membranes are designed for difficult-to-treat water sources, the company says, and are used for cleaning drinking water, wastewater, and industrial feedwater. The company claims they can function in virtually any raw water quality to produce water with high purity and low silt density.