Any advance in road-building technology would be welcome in Canada, where road surfaces often seem to start to crumble almost as soon as the construction equipment leaves the site. Researchers at a university in Singapore have presented what they say could be such an advance, a new type of concrete they are calling ConFlexPave. The key difference between this concrete and what we are used to? This one is bendable. Not only is it bendable, an attribute achieved by including polymer in the traditional concrete recipe, but it is significantly more durable.

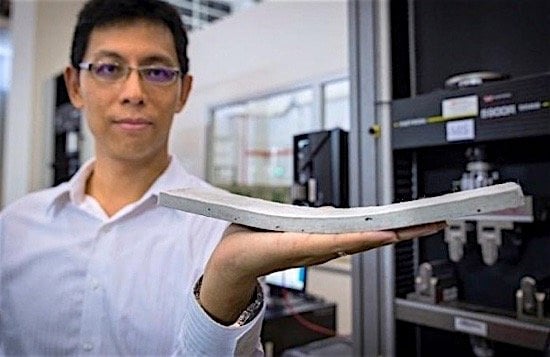

The director of technical services at Nanyang Technological University (NTU) of Sinagpore, Koh Chwee, called the bendable concrete “game-changing technology,” saying it will benefit the construction industry by reducing labour-intensive on-site work and reducing construction time, improve workers’ safety, and reduce the need for resurfacing roads, thus benefit road users. It does all of this because the concrete can be made in thinner, lighter slabs that are easier to install. The idea is that pre-fabricated slabs of ConFlexPave can be slotted in where needed to replace damaged sections in an existing roadway.

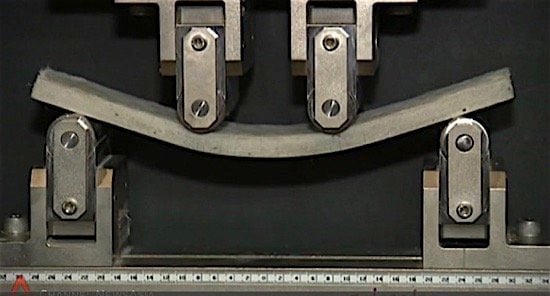

According to the scientists, the key breakthrough was in understanding how the components of the material, consisting of water, gravel, sand and polymer microfibres, interact with each other at the microscopic level. The addition of the synthetic materials allows the concrete to flex and bend, while still providing a non-slip surface that enhances skid resistance. The microfibres, which are described as thinner than the width of a human hair, distribute the weight across the whole slab. The result is concrete that is “tough as metal and at least twice as strong as conventional concrete under bending.” Since the concrete is twice as strong, it can be used at half the thickness of regular concrete, making it easier and safer to transport.

Higher production costs of the new concrete are expected to be offset by lower life-cycle maintenance costs, the scientists say. The material will undergo a series of real world tests over the next three years. There is no mention of how cold climate could affect its performance.