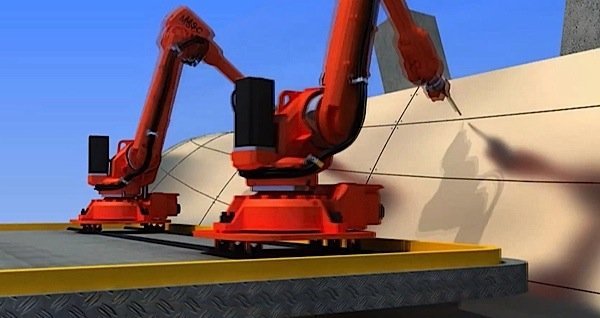

An outspoken and controversial architect from Austria says that robotic construction and 3D printing are the future of architecture, whether we like it or not, and architects who fail to adapt to the new reality will not survive. Wolf Prix, whose architecture firm Coop Himmelb(l)au is currently completing work on an art museum in the Chinese city of Shenzhen, is famous for his bold views and equally bold designs. The Shenzhen building has the typically complex shape favoured by Prix in his design, and is being assembled in part by robots, using plans generated by a building information modeling (BIM) system. The architect says the work the robots are doing would normally take 160 workers eight months to complete: instead, it will take eight workers twelve weeks.

Robots can clearly build faster and more economically than human workers, while giving architects the freedom to explore a “new aesthetic.” Using 3D printing and robots makes it easier to create buildings with complex shapes. This is good not only for aesthetics, but for economics. Normally, the more complex the form, the more expensive it is to build, and the longer it takes.

But Westerners are not embracing the new methods as enthusiastically as they should, according to Prix. On a recent project in the French city of Lyon, the architect said he was unable to convince the client to use the new methods he espouses. They refused to use robots, he said, saying it was “too complicated,” the usual explanation “when people don’t want to innovate.”

Never one to shy away from controversy, Prix believes it is no coincidence that the revolutionary work being done today is happening in China. Speaking to ArchDaily, Prix said the Chinese will ultimately bring these more efficient construction methods to the West. If they succeed, it could bring about “a big revolution” in the construction industry. “Sooner or later, Chinese companies will do it and will buy all of the stupid, slow building companies in Europe.”

The use of 3D printing and robotic assembly does not have to be confined to grand buildings like museums and concert halls. Prix sees the techniques being used for mass producing housing for refugees as well. With hundreds of thousands of refugees flooding into countries like Austria and Germany, building houses for them out of bricks and concrete would take a long time and cost a great deal. But 3D printing prefabricated parts and putting them together with robots can be done very fast and economically, he says.

Prix is not unaware of the possible social consequences of an increasingly automated construction industry, especially for construction workers. Many could be out of work, he concedes, once their jobs are replaced by machines. If construction by robots takes over on a global scale, it will spark a revolution in an industry that has remained largely the same for 5000 years, said Prix in an interview with ArchDaily.

That revolution, he believes, is coming whether we want it or not, and it will destroy the past 5000 years of “thinking in bricks.” Whether architecture survives depends on whether architects make themselves economically viable, and capable of solving “complex problems with complex solutions.”